Schaeffler, a dominant force in the automotive and industrial sectors, announces a quantum leap for hydrogen-powered transportation: their next-generation metallic bipolar plates for PEM fuel cells. These plates surpass conventional standards, with a design primed for mass production and a cutting-edge coating process that assures fuel cell longevity.

Highlighting a performance enhancement, these plates boast a power density that outperforms their predecessors by 20%. Matthias Zink, CEO of Automotive Technologies at Schaeffler AG, accentuates Schaeffler’s forward momentum: “When it comes to driving systems for commercial vehicles, Schaeffler is also investing in hydrogen, especially for long-haul applications. We are developing both individual components and complete subsystems for fuel cells and are gearing up for their full-scale industrialization.”

Production commences at a dedicated Herzogenaurach facility, capable of crafting tens of thousands of units. Strategically nestled within Schaeffler’s hydrogen nexus, this automated hub brims with avant-garde testing tools. Notably, this nexus also crafts larger plates pivotal for electrolyzers, underscoring Schaeffler’s allegiance to green hydrogen. By 2024, Haguenau, France, will witness the surge of these plates under the ‘Innoplate’ banner, a synergy between Schaeffler and Symbio.

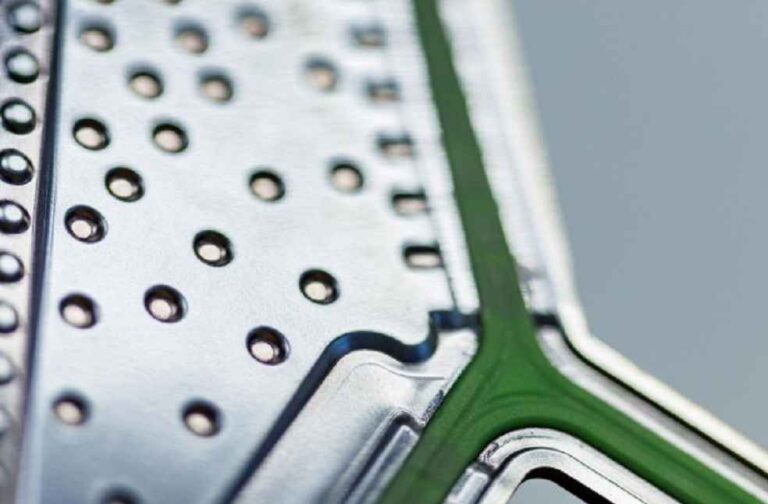

These plates, reminiscent of a DIN A4 envelope in size and weighing a trifling 60 grams, bear the brunt of fuel cell operations. They deftly channel process gases, coolant, and shepherd the removal of chemically-produced water. Dr. Jochen Schröder, Schaeffler’s E-Mobility luminary, elucidates, “The finer and more precise the structures on the bipolar plate, the more efficient the plate is.”

For vehicular applications, these plates are stacked in the hundreds, forming the crux of a fuel cell stack, which can achieve power outputs up to 140 kW, apt for light commercial vehicles. For heavier commercial vehicles, two such stacks become requisite.

Designed with an industrial blueprint, these plates epitomize Schaeffler’s ‘design for manufacturing’ (DFM) ethos. Drawing upon seasoned expertise in metalwork, these plates achieve a finesse seldom seen in ultra-thin structures.

The standout ‘Enertect’ coating system, bespoke for these plates, amplifies their uniqueness. Jochen Schröder expounds, “Thanks to our capabilities in surface technology, we can offer each customer an application-specific coating solution. This means we can meet each customer’s requirements in terms of balancing cost, performance, and manufacturing-related CO2 emissions.”

Schaeffler’s relentless drive toward innovation and sustainable progression is palpable. As global transportation gravitates towards greener horizons, Schaeffler’s advancements in fuel cell technology are poised to play a pivotal role in this paradigm shift.

LATEST | Swickard and Spitzer’s Ambitious Expansions Drive U.S. Auto Growth