Signaling a significant shift in the semiconductor industry, Renesas Electronics Corporation, a leading supplier of advanced semiconductor solutions, and Wolfspeed, Inc., the global pacesetter in silicon carbide technology, announced a ten-year wafer supply agreement today. The $2 billion deposit by Renesas will ensure a steady supply of silicon carbide bare and epitaxial wafers from Wolfspeed, thereby enabling Renesas to ramp up production of silicon carbide power semiconductors by 2025.

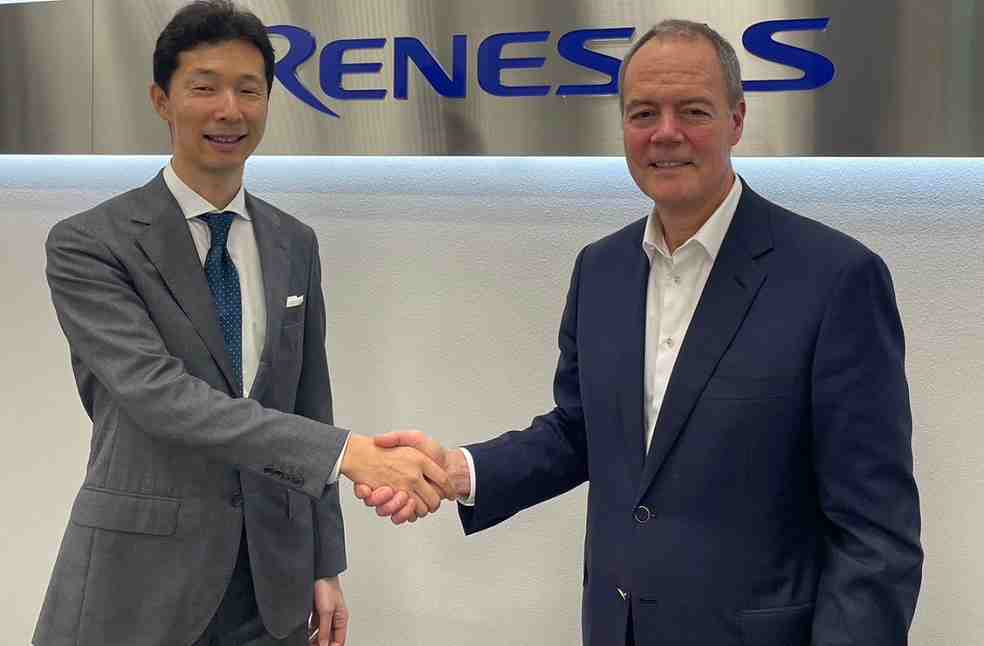

The signing ceremony of the deal, which emphasizes the companies’ shared vision for a silicon to silicon carbide transition in the semiconductor industry, was held at Renesas’ headquarters in Tokyo.

The burgeoning demand for efficient power semiconductors, integral in supplying and managing electricity, is particularly evident in the automotive and industrial sectors. This is largely driven by the rise of electric vehicles (EVs) and the expansion of renewable energy sources. In response, Renesas has accelerated efforts to increase its manufacturing capacity. This includes the reactivation of its Kofu Factory to produce Insulated Gate Bipolar Transistors (IGBTs) and the establishment of a silicon carbide production line at the Takasaki Factory.

Silicon carbide devices boast several advantages over conventional silicon power semiconductors, including higher energy efficiency, superior power density, and lower system cost. These attributes have spurred their adoption across high-volume applications such as EVs, renewable energy, storage, charging infrastructure, and industrial power supplies.

Hidetoshi Shibata, President and CEO of Renesas, expressed his optimism, “The wafer supply agreement with Wolfspeed will provide Renesas with a stable, long-term supply base of high-quality silicon carbide wafers. This empowers Renesas to scale our power semiconductor offerings to better serve customers’ vast array of applications. We are now poised to elevate ourselves as a key player in the accelerating silicon carbide market.”

Gregg Lowe, President and CEO of Wolfspeed, stated, “With the steepening demand for silicon carbide across the automotive, industrial, and energy sectors, it’s critically important we have best-in-class power semiconductor customers like Renesas to help lead the global transition from silicon to silicon carbide. For more than 35 years, Wolfspeed has focused on producing silicon carbide wafers and high-quality power devices, and this relationship marks an important step in our mission to save the world energy.”

Renesas’ $2 billion deposit will fund Wolfspeed’s capacity construction projects, including the John Palmour Manufacturing Center for Silicon Carbide (the JP), the world’s largest silicon carbide materials factory located in Chatham County, North Carolina. The facility is designed to expand Wolfspeed’s current silicon carbide production capacity more than tenfold. It will primarily manufacture 200mm silicon carbide wafers, which offer 1.7 times the size of 150mm wafers, resulting in more chips per wafer and ultimately, lower device costs.

This monumental partnership between Renesas and Wolfspeed not only catalyzes a paradigm shift in the semiconductor industry, but also paves the way for more energy-efficient and cost-effective solutions in an increasingly energy-conscious world.

AUTO TECH: The Sky’s the Limit: Are we Poised for a Future of Flying Cars?