The automotive industry is undergoing a major shift driven by advancements in business models, supply chains, and in-vehicle technologies such as artificial intelligence (AI). While promising, these changes often increase costs, particularly with high-performance AI-enabled system-on-chips (SoCs) and the growing demand for electric vehicle (EV) batteries.

Automakers face the challenge of reducing expenses without compromising the next-generation experiences consumers expect. Intel proposes a solution through a comprehensive, systems-based approach to vehicle design.

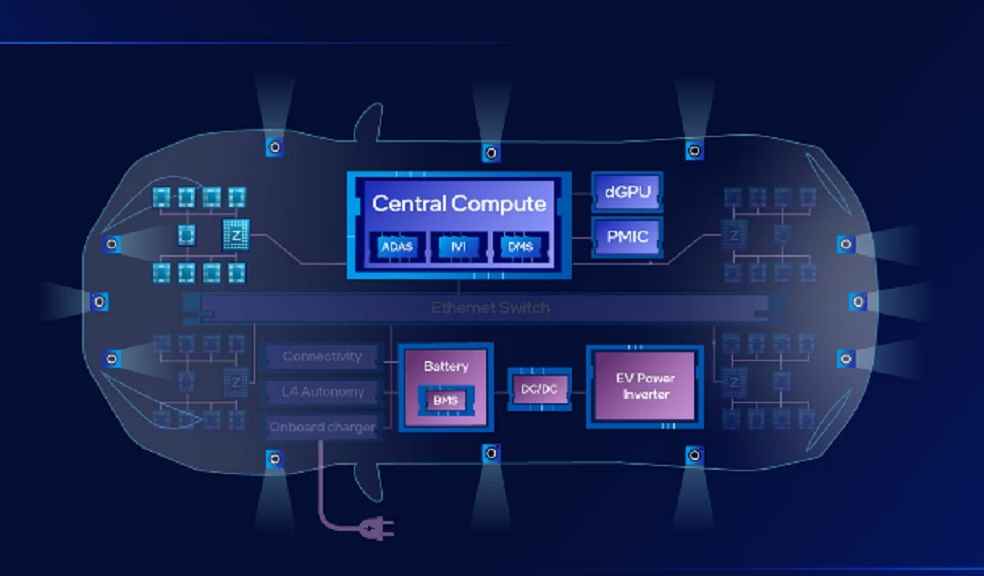

Traditional cost optimization methods, focusing on individual components, fall short. Intel’s strategy integrates three key elements: software-defined in-cabin computing, intelligent energy management, and data-center-like workload management. This comprehensive approach enables seamless workload movement between software-defined central compute systems and zonal compute subsystems, optimizing cost, performance, and energy efficiency.

Current vehicle architectures, often siloed, lead to inefficiencies. For instance, many EVs support features such as monitoring external cameras for security even when the vehicle is off. This typically drains the battery due to the high power consumption of the in-cabin compute subsystem.

Intel suggests migrating such workloads to lower-power devices like zonal controllers, which would only activate the central computing system when necessary. This strategy saves energy and reduces the total number of electronic control units (ECUs) in the vehicle.

Intelligent power policies can reduce energy consumption. Simple adjustments, such as turning off the ADAS ECU while charging or modulating power use based on environmental conditions have substantial impacts. These concepts, derived from the PC industry’s ACPI standards, are now being adapted for automotive use through the new SAE Vehicle Platform Power Management Standard.

Intel advocates for a software-defined design philosophy where compute, memory, and I/O are pooled and dynamically allocated. This approach, akin to data center operations, transforms a vehicle’s electrical/electronic (E/E) architecture from fixed-function sockets to a flexible pool of resources. This shift enables new system-level strategies that deliver enhanced consumer experiences while maintaining cost efficiency.

LATEST | UK Auto Industry Seeks Japanese Investment to Overcome Production Challenges