Daihatsu Motor Co’s unveiling of the me:MO concept car at the Japan Mobility Show marked a significant leap forward for the automotive sector. This subsidiary of Toyota introduced a small electric vehicle distinguished by its 3D-printed components, signifying an era of enhanced customization and environmental awareness.

The me:MO stands out for its adaptability, allowing potential owners to modify both the exterior and interior to their liking. Daihatsu’s mission, focusing on customer-centric innovation, is evident in this concept. The design addresses current preferences for eco-friendly and flexible mobility solutions.

Daihatsu’s approach to car design emphasizes a modular structure, permitting alterations in form and function. This adaptability caters to the evolving needs and lifestyles of customers, promoting sustainability through prolonged vehicle use.

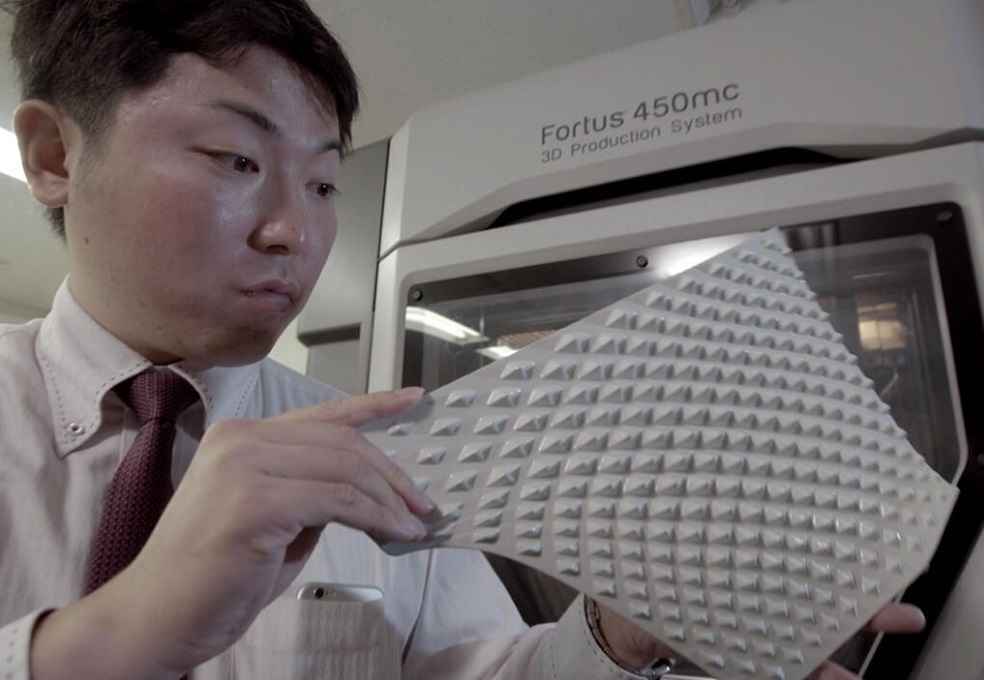

Details about the specific 3D printing technologies and materials used in me:MO remains undisclosed. Industry experts believe large-format fused deposition might be the chosen method, suitable for producing sizable parts in various thermoplastics and hues. This method aligns with the growing trend of vehicle personalization.

The me:MO’s compact size, a mere 3 meters, facilitates the incorporation of 3D-printed decorative elements both on its body and within the cabin, enhancing its allure. The transition of this concept into a market-ready model remains a subject of anticipation within the automotive circles.

AUTO TECH | CES 2024: Honda, Kia, Hyundai Unveil Future in EV Innovation