Continental, a pioneer in tire manufacturing, has made a major leap forward in its sustainability journey by securing a long-term purchase agreement with Pyrum Innovations. This partnership centers on procuring high-quality recovered carbon black (rCB) from end-of-life tires, marking a notable advance in Continental’s environmental commitment.

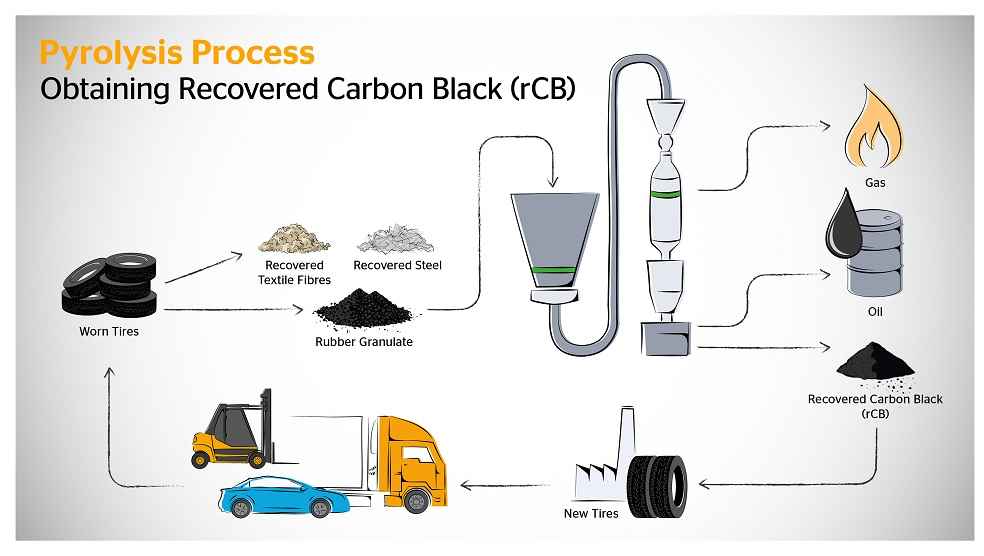

The recycled carbon black will play a crucial role in the future series production of Continental’s passenger car tires, reinforcing the collaboration that began with a development agreement in 2022. Both companies aim to optimize and expand end-of-life tire recycling through advanced pyrolysis technology.

Carbon black enhances the stability, strength, and durability of rubber compounds in tire production. Traditionally derived from fossil fuels, its production contributes significantly to CO2 emissions. Incorporating recycled carbon black allows Continental to reduce its dependence on fossil raw materials and lower its carbon footprint. Continental’s passenger car tires contain 15 to 20 percent soot, depending on the model. This innovative use of recycled materials aligns with Continental’s goal of achieving over 40 percent renewable and recycled materials in its tires by 2030.

The recycling process for end-of-life tires involves complex technologies to efficiently separate, clean, and reuse materials without compromising safety or quality. Jorge Almeida, Head of Sustainability at Continental Tires, emphasized the importance of shifting from an ‘end-of-life’ to an ‘end-of-use’ concept.

“Recycled raw materials are becoming increasingly important in our tire production. To further increase the circularity of our products, we need to think differently. We need to move from an “end-of-life” to an “end-of-use” tire concept. This means that the end of a tire’s intended use phase must become the beginning of a new opportunity.” he stated. This innovative approach ensures that materials from end-of-use tires are reintegrated into the production cycle, promoting sustainability.

The expanded cooperation with Pyrum Innovations represents a critical milestone in Continental’s sustainability strategy. Pascal Klein, CEO of Pyrum Innovations, highlighted the progress made: “The expansion of our cooperation with Continental is a very important step for us. Together, we have already succeeded in ensuring that all newly produced forklift tires at the Continental tire plant in Korbach, Hesse, contain our sustainable carbon black.” This success underscores the potential of circular economy practices in achieving environmental goals.

As part of its comprehensive sustainability strategy, Continental aims to use 100 percent sustainable materials in its tires by 2050. Recycled materials will play a crucial role in this endeavor, transforming end-of-life tires into valuable resources for new tire production. This closed-loop system is integral to Continental’s vision of a more sustainable future for the tire industry.

DON’T MISS | China-Europe Auto Industry Bonds Grow Stronger with NEV Investments