The BMW Group is dedicating a hefty investment of €100 million towards establishing a state-of-the-art battery testing center at its Wackersdorf location in Upper Palatinate by 2026, marking a substantial stride in its e-mobility trajectory. This investment accentuates the automotive giant’s alignment with the global momentum towards cleaner and more sustainable electric vehicle technologies.

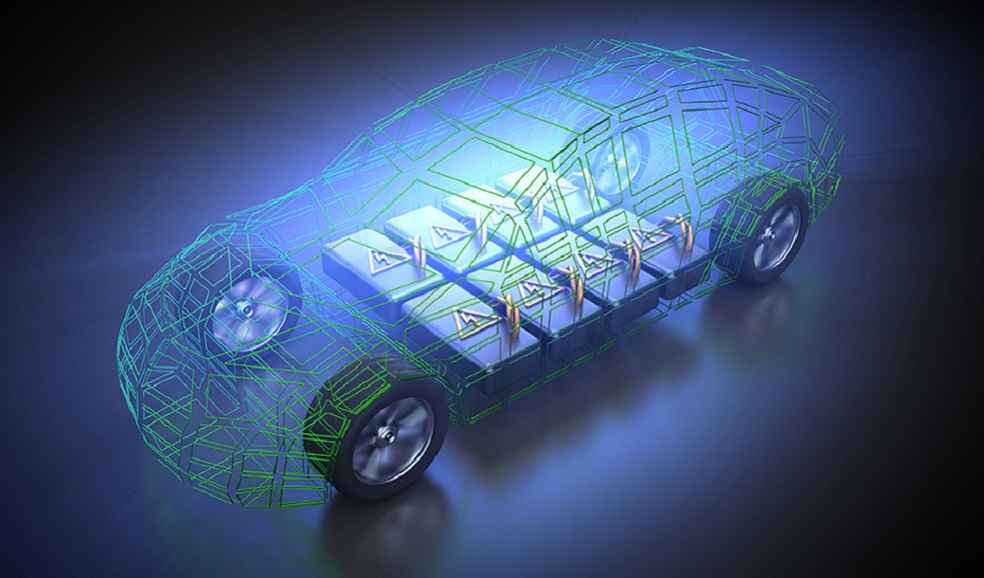

Destined to blend seamlessly with the existing infrastructure, the new battery testing center symbolizes a crucial milestone in the road toward electric vehicle refinement. The first wave of deliverables concerning the development of high-voltage batteries is anticipated to transition into regular operation by mid-2024. Spanning a substantial area of 8,442 m², this facility will serve as a rigorous testing ground for high-voltage batteries and other pivotal electric powertrain components, well ahead of their slated production timelines for future BMW models.

Site Manager Christoph Peters highlighted the strategic essence of the Wackersdorf location in BMW’s overarching e-mobility blueprint. The inception of this battery testing center is poised to substantially enrich the operational spectrum at Wackersdorf. “In addition to supplying our overseas plants, cockpit production and, from 2024, door production for Rolls-Royce models, this will become Wackersdorf’s fourth main area of activity. This, in turn, strengthens our location’s future viability,” stated Peters.

A lion’s share of the €100 million fund is allocated towards the procurement of sophisticated test bench technology and necessary infrastructural upgrades. One notable facet of this transformation is Hall 80, which is presently undergoing modifications to align with its newfound purpose. Once a blueprint of the 1980s for a reprocessing facility, it’s now being hailed by Peters as a “symbol of our plant’s electric future”.

With structural alterations progressing smoothly, including the installation of a new floor slab, the venue is on track to inaugurate its first segment by mid-2024. The forthcoming deployment of ‘battery testers’ is slated to kickstart an exhaustive round-the-clock analysis of battery cells early in their developmental phase. This robust testing paradigm is crucial for evaluating the electrical performance of individual battery cells across diverse charging and discharging scenarios, thereby enabling authentic simulation of use cases relevant to customers, long before the vehicle hits the asphalt.

This bold maneuver by BMW is emblematic of the broader e-mobility transformation unfolding globally. Post-2025, the testing center is set to morph into a validation hub for BMW’s battery-electric vehicles ahead of their series production, ensuring adherence to the high-quality benchmarks. Equipped with sophisticated ‘shakers’ for vibration and shock tests, complex driving simulations, and a plethora of other rigorous assessments critical for electric vehicle type approval, the Wackersdorf battery testing center emerges as a pivotal asset in BMW’s comprehensive strategy to pioneer electromobility into a new era.

BMW’s substantial investment resonates with the global narrative advocating for electric vehicle technology, reverberating far beyond the perimeters of Wackersdorf. The progressive march of electric vehicles is not just a transient trend but an enduring global transition towards a more sustainable and eco-friendly automotive future.

DON’T MISS | Lucid Group Ignites Saudi Auto Sector with First-Ever Electric Car Facility