Marking a significant milestone towards a greener future, BMW Group unveils plans for a cutting-edge logistics center catering to fifth-generation high-voltage batteries at Leipzig’s northern industrial zone. This announcement augments the Group’s dedication to electromobility and investment within Plant Leipzig.

On a 12-hectare expanse with eight hectares earmarked for initial development, the blueprint includes a sophisticated logistics hall and an office edifice, both poised for a mid-2024 unveiling.

A New Era Unfolds

To herald the construction onset of the Supply Centre North, luminaries such as Petra Peterhänsel, Plant Director; Jens Köhler, Works Council Chairman; Frank Hager, Head of Production for High-Voltage Batteries; and Clemens Schülke, Leipzig’s Mayor, assembled for the ceremony. Representatives from Max Bögl Stiftung & Co KG, the entrusted construction entity, bolstered the collaborative ambiance.

Emphasizing Leipzig’s dynamic economic landscape, Mayor Clemens Schülke observed, “With this extension, BMW is sending out a clear signal around Leipzig as a base and electromobility.”

Electromobility Ascends

With an impressive 38,000 m2 combined gross area in the first construction stage, further expansion plans could bring the total investment to a whopping 100 million euros. Upon completion, the Supply Centre North is set to accommodate approximately 500 employees.

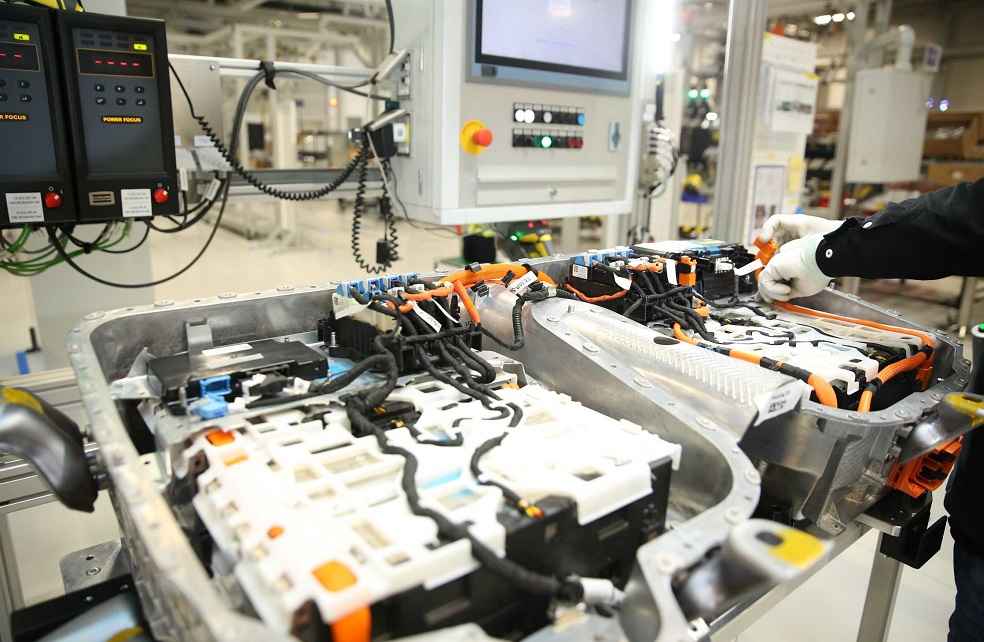

By 2026, BMW’s aspiration encompasses selling one-third of its fleet as fully electric vehicles, implying a burgeoning demand for high-voltage batteries. Plant Leipzig, an indispensable e-component contributor, equips BMW’s electric vehicle ensemble with one in three battery modules.

Sustainability Embodied

Transcending standard compliances, the avant-garde logistics hall stands as the epitome of rigorous environmental protocols. Shunning fossil fuel dependency, photovoltaic systems are projected to yield around 3,000 kW during optimal output. Diverse green initiatives comprise an eco-centric office rooftop, strategically positioned trees for ambient cooling, and an infusion of 5,700 shrubs and trees, enhancing the city’s verdant pursuits.

Exterior infrastructure further promotes eco-sensibilities with insect-compatible lighting and parking zones fortified with electric charging hubs.

E-component Production: Leipzig’s Pulse

Electromobility’s future lies in e-component production, guaranteeing job retention and spawning new career avenues. Plant Leipzig stands poised to lead all facets of high-voltage battery fabrication, with battery ensemble operations gearing up for a launch next year.

BMW’s unwavering allegiance is epitomized by a colossal investment of up to 1 billion euros earmarked for e-component augmentation at Leipzig. Awaiting a 2024 launch, the plant gears up to present its electric marvel, the novel MINI Countryman, equipped with high-voltage batteries conceived directly within Plant Leipzig.

This venture underscores BMW’s unrelenting dedication to sustainable breakthroughs, cementing its stature as a luminary within the electric mobility epoch.

LATEST | Electromobility Shift Ignites Job Fears, Dents Confidence in German Auto Sector