Multinational automotive manufacturer STELLANTIS, is launching a bold strategy to maintain its profit margins amid escalating EV competition, particularly from electric vehicle manufacturers like BYD and Tesla. The company is setting its sights on suppliers, urging them to offer improved deals on components. This move is primarily driven by the intensifying race in the EV market and the need to make electric vehicles more affordable, a necessity underscored by the rise of lower-priced Chinese competitors.

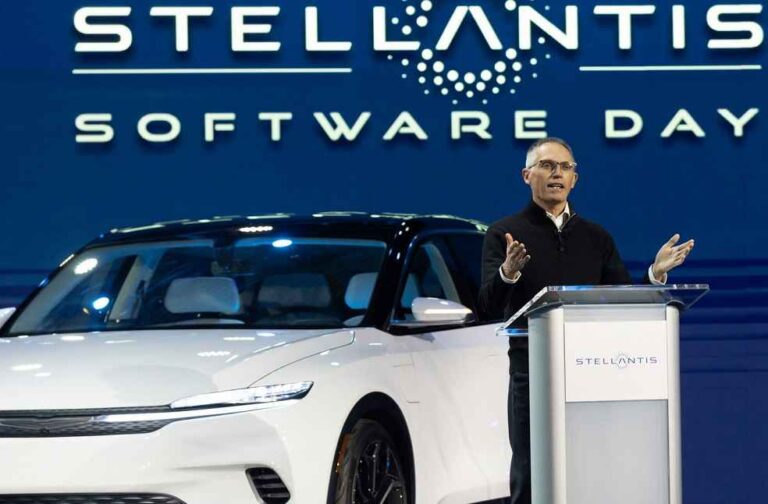

At the helm of this strategy is STELLANTIS’s CEO, Carlos Tavares. Having already achieved significant savings by reducing expenses in the company’s factories, he is encouraging suppliers to follow suit. On a recent media call, Tavares highlighted his expectations, stating, “Component makers should review what we have done in our own plants to progress on their side.”

STELLANTIS ‘s pursuit of cost-effectiveness is not limited to renegotiating supplier deals. The company has implemented rigorous measures in Italy and the United States, including job cuts and factory shutdowns. These actions, despite accompanying controversies such as accusations of skimping on janitorial work in Italy, underscore the intense pressures the global automaker is facing.

STELLANTIS is investing 30 billion euros ($33.1 billion) into electric vehicles (EVs) and software. In order to fend off potential semiconductor shortages—an issue concerning the entire auto industry—the company is forging strategic alliances with companies like Infineon Technologies, NXP Semiconductors, and Qualcomm. Furthermore, STELLANTIS is securing direct access to essential raw materials like manganese and nickel by acquiring equity stakes in mining companies.

The Chief Technology Officer of STELLANTIS, Ned Curic, commended Valeo, a supplier that has effectively managed supply-chain disruptions while keeping costs in check. However, he also issued a warning: not all suppliers have demonstrated such resilience, and those less adaptable might not survive the challenges that lie ahead.

Tavares expects that the steep costs associated with transitioning to EVs will necessitate further adjustments to STELLANTIS’s operations in Europe and the U.S. As the company makes these changes, it also faces pressure from the French and Italian governments to manufacture more affordable cars domestically in order to safeguard jobs.

Despite potential challenges, such as the emerging cost-of-living crisis that could dampen demand for higher-priced EVs in Europe, STELLANTIS projects a positive outlook for the rest of the year. The cost-saving measures implemented have already demonstrated their worth, propelling the company to achieve an adjusted operating income margin of 14.4 percent for the first half of the year—surpassing analysts’ forecast of 12.2 percent.

Tavares stated that logistical challenges in Europe, which led to thousands of cars being stranded, have largely been resolved. He added, “We still have a couple of things that we are going to solve during the month of August, namely getting rid of our backlog in some of our yards where our customers are still waiting for some cars.”

With its strategic supply chain transformation and aggressive cost-cutting measures, STELLANTIS is sending a clear signal to competitors and the wider industry. As automakers grapple with the shifting landscape of EV manufacturing and the challenges of supply chain disruptions, STELLANTIS’s proactive and assertive actions illustrate the lengths companies are willing to go to secure their competitive advantage and safeguard their profits.

NEW LAUNCH | Tesla Cybertruck Unveiled: Game-Changer in the EV Pickup Market